Whether or not the powerful agree, MANMADE CLIMATE CHANGE IS THE GREATEST CHALLENGE FACING OUR PLANET. We cannot rely on political or business leaders to effectively address this challenge. But designers can individually make a difference by radically rethinking building materials.

BUILDINGS account for 40% of carbon emissions – half from construction materials and half from building operations. Much progress has been made to reduce resources consumed by building operations, i.e. energy-efficient systems, passive climate-control strategies, water-saving devices, etc.

But much less progress has been made on ECOLOGICALLY-RESPECTFUL BUILDING MATERIALS. Architects habitually specify carbon-intensive materials: concrete (which alone accounts for up to 10% of carbon emissions globally), steel, glass and aluminum. In the name of sustainability, engineers rely on rapidly obsolete technology to reduce building energy, perpetuating a toxic cycle of discarded electronics and building materials.

Globalization has universalized these planet-depleting materials and technologies, erasing differences between buildings in dramatically different climates and cultures. Architects bemoan a reduced role in the building process dominated by developers and standardized building parts. Designers complain that innovation is curtailed by increased complexity and stifled by potential liability. We have become conductors, not composers. Occupants yawn, bored by generic buildings we have multiplied into generic cities. Continuing to specify harmful materials and technologies, architects accelerate the demise of both the planet and our profession.

The future of our planet requires radical rethinking of building materials – substituting carbon-intensive, toxic, or short-lived building materials with cradle-to-cradle environmentally respectful materials. The innovation this requires can resuscitate the design profession. All construction materials and building systems should be challenged and substituted with more sustainable designs.

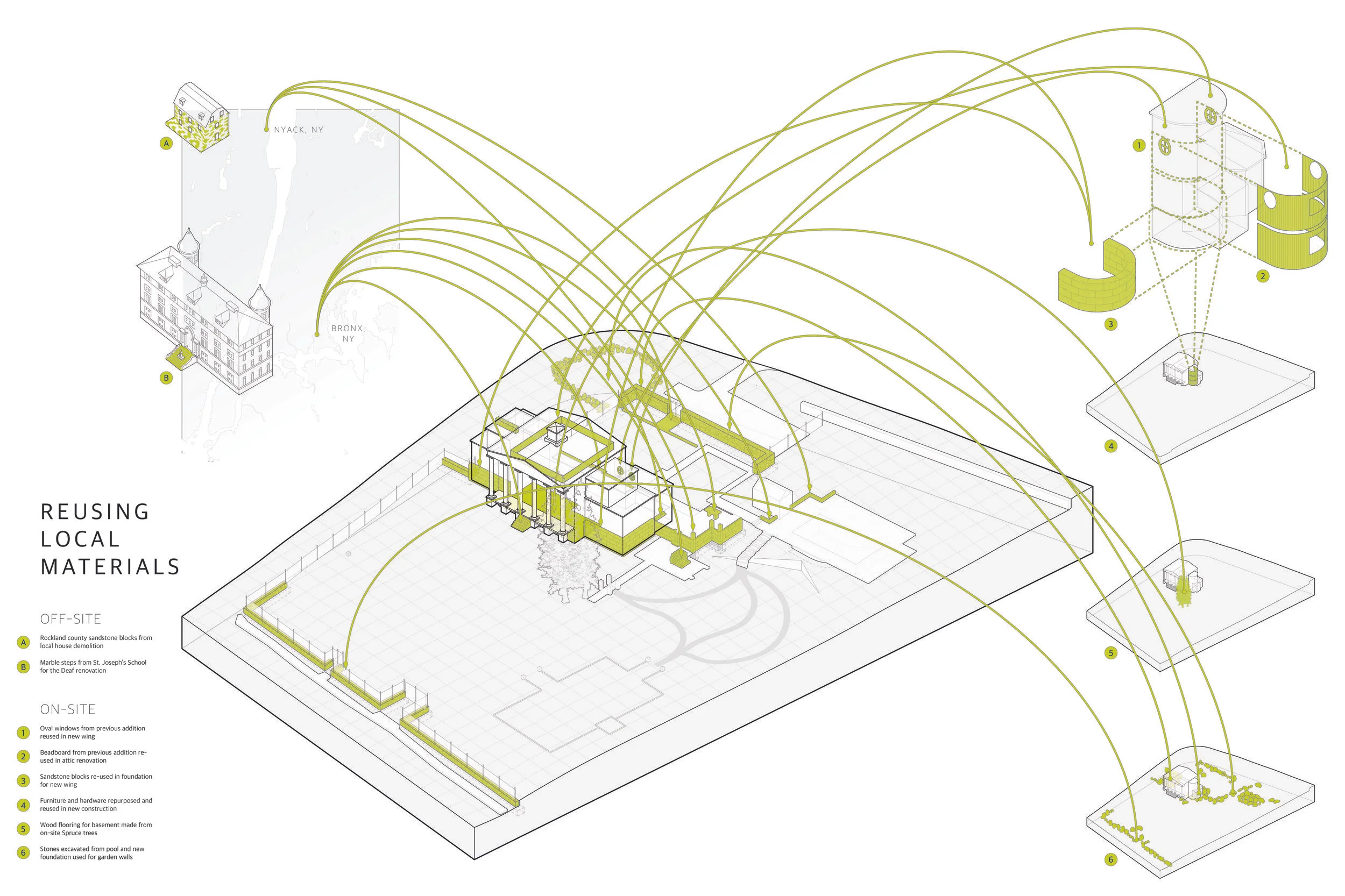

LOCAL MATERIALS – Start with materials on site, use site features for passive climate strategies, explore all possibilities of materials from nearby, and justify everything sourced from afar.

NON-TOXIC MATERIALS – Understand carbon footprint and toxicity of all materials, use building materials which minimize embodied energy and disruption of the earth, from extraction to demolition and disposal/reuse.

REUSED MATERIALS – Salvage existing materials where possible, design cradle-to-cradle next-use functionality into new materials. (Recycling is better than new, but still requires energy to reformulate into new products).

TIMELESS DESIGN – Research time-tested locally available materials and designs, update them for contemporary functions and aesthetics, favor reliable long-lived building systems, design for long-term use.

EXPERIMENTATION – Discover new sustainable materials, innovate with new or known materials, work with material suppliers to test prototypes, demand innovation from material suppliers.

Truly sustainable design requires resistance against the status quo of the construction and materials industries. Resistance raises questions about the trajectory of globalism, industrialization, digital technology and capitalism, as outlined below. For clarity, “POST-“ is not “ANTI-“. Instead, “POST-“ seeks to build on the strengths of the existing order while addressing its flaws. “POST-“ does not reject current systems but critically selects and improves.

I believe Sustainable Architecture of the Future is:

POST-GLOBAL: Sustainable building products privilege local sources where environmental impact is known and measurable and carbon footprint for transportation is minimized. The best ideas generated globally are tailored to site conditions and materials. Sourcing and manufacturing is distributed (i.e. local), not centralized. Locals live in proximity to material extraction and fabrication, owning the consequences of their environmental impact which facilitates holistic cost/benefit evaluation. Architecture (both material and design) fits its context. Pre-global constraints (e.g. proximity of materials) are selectively re-introduced.

POST-INDUSTRIAL: Enabled by new digital manufacturing tools, mass production in centralized locations -- where materials come from afar and products are shipped globally – is supplemented / replaced by customizable local production. In place of centrally manufactured modular building parts (IGU), portable manufacturing modules utilizing local raw materials and labor generate customized solutions (stick-built windows). Efficiency of production is balanced by efficient (on-site) maintenance and repair (i.e. replacing broken seals or glass on-site rather than at the overseas factory). Product designs are basic enough to be understood by local repairmen in the distant future. Pre-industrial ideas (custom vs. mass production, distributed vs. concentrated fabrication) are selectively re-introduced. Standard unit dimensions developed locally and persisting over time assist manufacturing economies of scale.

POST-DIGITAL: Digital design tools are redirected from the current practice of multiplying off-the-shelf building parts from material suppliers via BIM software. Instead, digital tools are used: (1) to EVALUATE (and therefore minimize) the environmental impact of building designs and materials (from extraction to disposal); and (2) to CUSTOMIZE designs to harness climate, utilize local materials, and anticipate re-use. To operate buildings, digital gadgets with short life-spans are avoided in favor of resilient, long-lasting manual controls (e.g. physical key instead of electronic). Radically basic manual controls are selectively re-introduced.

POST-CAPITALIST: Rate-of-return formulas overweighting short-term events and ignoring long-term consequences are thrown out. Instead, building materials are made to last, breaking the business cycle of planned obsolescence. Product designs are more robust than required for initial sale (i.e. durable enough to avoid tarnishing the manufacturer’s brand) – they are made to last for their anticipated life-span and pre-designed for disposal/re-use. Return on investment is calculated not just for the manufacturer, builder, and initial owner but incorporate larger returns to society over the life of the building – environmental and social costs and benefits are considered along with financial returns.

POST- Architecture can only be practiced in a setting which encourages for experimentation – where failure is allowed. What better setting than the designer’s own home. These are the principals that guide our building project in Brazil.

Walter Cain